Continuous casting intermediate ladle is one of the key equipments in continuous casting process, which has the function of stabilizing and diverting the flow, and plays a very important role in the continuous casting operation and assuring the quality of molten steel. The stable pouring of the intermediate package is conducive to prolonging the residence time of molten steel in the intermediate package, and homogenizing the temperature and composition of molten steel. However, the working layer near the impact zone of the ladle is eroded too quickly by the molten steel, which restricts the service life of the ladle. By adding a flow stabilizer in the impact zone of the ladle, the scouring of the working layer of the ladle near the impact zone by the molten steel can be slowed down, thus further improving the ladle age. After installing the flow stabilizer, the trajectory of steel in the intermediate ladle has changed, reducing the additional circulation, basically eliminating the short-circuit flow, reducing the rolled slag, and promoting the uplift of inclusions. However, there are still corners on both sides of the intermediate package, seat brick, water outlet scour erosion serious, high temperature problems, reducing the service life of the intermediate package, resulting in increased heat exchange dumping billet, high consumption of steel and steel materials, as well as increase in refractory material costs. Therefore, it is necessary to improve and optimize the metallurgical process of continuous casting ladle to improve the service life of the ladle, ensure the cleanliness of molten steel, improve the quality of billet and meet the requirements of users. By taking effective measures, Laiwu Branch Steelmaking Plant has achieved better metallurgical results.

Process flow and problems

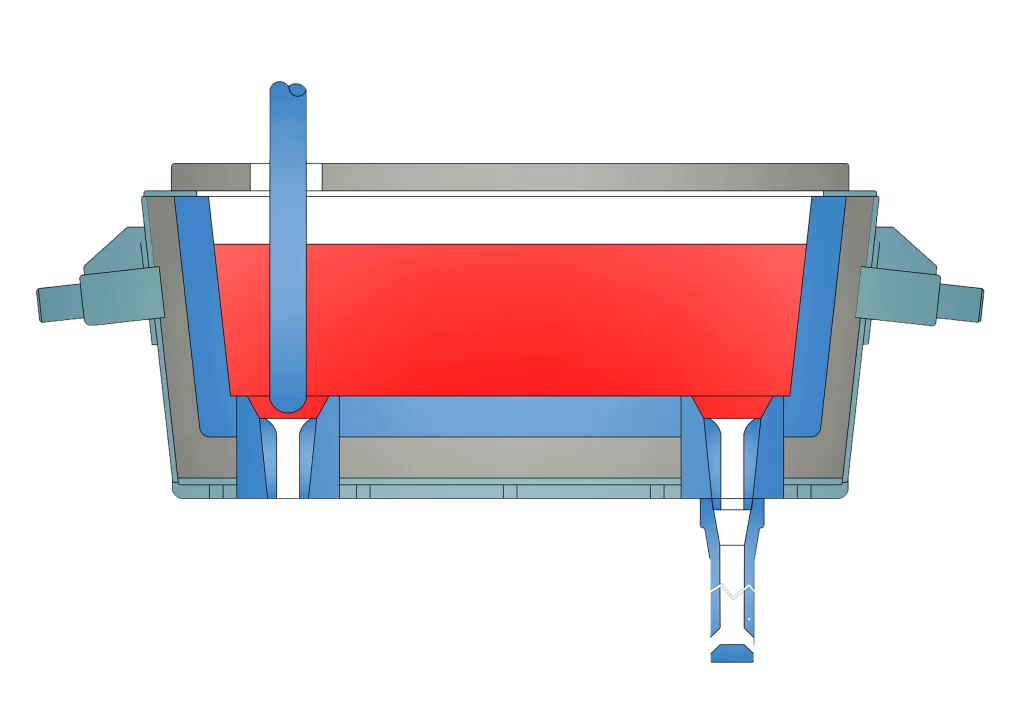

Process flow: 50t re-blowing converter → refining → continuous casting ladle rotary table → intermediate ladle → flow stabilizer → upper water outlet → crystallizer.

(1) Lai Steel Steel Plant old area of continuous casting machine intermediate packet working layer after many expansion and transformation, the working lining is relatively thin, the packet wall working lining thickness of 80mm or so, and the intermediate packet shell has not been updated for many years of use, the packet shell deformation is serious, resulting in uneven thickness of the packet wall. Recently used more than 48h intermediate package working layer slag line parts of the erosion thickness of more than 40mm, intermediate package slag line, impact zone erosion is serious. Intermediate package slag line parts erosion, resulting in the part of the temperature measurement than other parts of the high 50 ℃ or more.

(2)The current continuous casting machine plug rod intermediate package production, plug rod head by the intermediate package of steel uneven, strong scouring, in the use of 12h after the plug rod head uneven, too fast erosion, resulting in the plug rod intermediate package can not be stable flow control, is a key factor in limiting the service life of the plug rod intermediate package.

(3)Sizing intermediate pack in the late service life, intermediate pack on the water mouth too fast erosion, zirconium core fall off, often water mouth blockage, continuous casting flow problems, seriously affecting the efficient production of continuous casting. The above factors lead to more unplanned replacement of the intermediate pack, seriously affecting the improvement of the life of the intermediate pack, bringing greater risks to the safety and stable production of continuous casting machine.

Improvement measures

1.Tundish slag line magnesium carbon brick composite repair technology

The intermediate package resistant material is divided into permanent layer, working layer two parts, the permanent layer is mainly used for the intermediate package thermal insulation, erosion resistance is poor; working layer is mainly used to resist the erosion of high temperature molten steel, steel slag, thermal insulation effect is relatively poor. Improve the anti-erosion performance of the intermediate ladle slag line is mainly improved by optimizing the working layer.

Through the research and development of an intermediate ladle slag line magnesium carbon brick masonry process, according to the intermediate ladle slag line erosion width, intermediate ladle working layer thickness, the design of a 300mm × 300mm × 30mm specifications of the intermediate ladle slag line special magnesium carbon bricks, the intermediate ladle working layer material for magnesium dry material. According to the different erosion conditions in the intermediate package, improve the material of magnesium dry material in the slag line part of the intermediate package, and improve the anti-erosion performance of magnesium dry material in the slag line part. Magnesium dry type material is divided into slag line magnesium dry type material, bag bottom magnesium dry type material two kinds, the intermediate bag slag line parts below and the bottom of the intermediate bag use bag bottom magnesium dry type material, intermediate bag slag line parts use special magnesium dry type material. In the preparation of the middle pack, after the knotting of the permanent layer of the middle pack is completed, the knotting of the working layer of the middle pack is carried out. First fill the intermediate packet slag line part of the following packet bottom magnesium dry material, and then along the intermediate packet permanent layer of the inner wall to place a circle between the packet slag line special magnesium-carbon bricks, and finally fill the slag line magnesium dry material, after 1.5 ~ 2.0h medium and small fire baking after molding.

2.Tundish impact zone magnesium plate combination repair masonry

Increase the thickness of the working layer in the impact zone of the intermediate packet, limited by the narrow space in the impact zone of the intermediate packet, the thickness of the permanent layer in the impact zone of the intermediate packet is thinned from 200 to 220 mm to 150 to 170 mm, and the thickness of the working layer in the impact zone of the intermediate packet is increased from 80 to 100 mm to 130 to 150 mm accordingly. increasing the thickness of the working layer in the impact zone of the intermediate packet, the anti-erosion ability of the intermediate packet can be significantly improved. Erosion resistance of the middle pack impact zone can be significantly improved by increasing the thickness of the working layer of the impact zone.

Research and development of a middle pack impact zone magnesium plate combination masonry technology, according to the shape and size of the middle pack design middle pack impact zone special magnesium plate. The magnesium plate adopts the intermediate package dry material knotting molding, divided into three kinds of outer arc plate, side arc plate, side plate, magnesium outer arc plate, side arc plate thickness of 100mm, magnesium side plate thickness of 50mm. the intermediate package impact zone magnesium plate outer arc plate, side arc plate, side plate combination of the intermediate package impact zone working layer for protection. After the intermediate packet working layer knotted, in the intermediate packet impact area installation of flow stabilizer, magnesium outer arc plate installed in the stabilizer above, two magnesium side arc plate installed in the stabilizer left and right sides, two magnesium side plate installed in the impact area on both sides of the corners, installed after the use of coated material for bonding, after 1.5 ~ 2.0h medium and small fire baking after molding.

3.Continuous casting intermediate package long-life water uptake

In order to solve the problem of intermediate packet upper water outlet too fast erosion, zirconium core falling off, research and development use a new type of long-life upper water outlet, the inverted upper water outlet heightened, increase the thickness of magnesium and carbon protection layer on the upper part of the upper water outlet zirconium core, reduce the erosion of molten steel on the zirconium core; the overall increase in the thickness of the upper water outlet zirconium core, improve the erosion resistance of the upper water outlet zirconium core.

(1)Design of external dimensions. The height of the upper spout is increased from 95mm to 145mm, the upper end of the upper spout zirconium core is equipped with additional magnesium carbon protection resistant material, the thickness of magnesium carbon protection resistant material is 20mm, which plays a role in isolating the zirconium core of the upper spout from the steel and reduces the erosion of steel on the upper end of the zirconium core by direct scouring.

(2)Optimization of inner cavity zirconium material. The height of the upper spout zirconium core body increased from 80mm to 125mm, the thickness of the upper spout zirconium core body increased by 2mm, and the hole at the upper end of the upper spout zirconium core that is in direct contact with molten steel is designed as an R-arc, with a radius of 5mm, which improves the strength of the upper spout zirconium core and cushions the molten steel against the impact on the zirconium core.

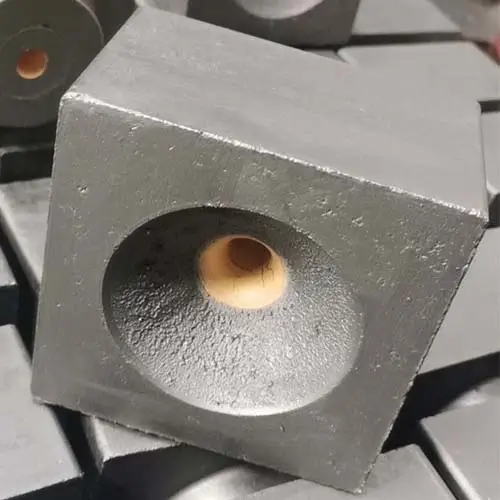

4.Plug bar center pack combination cofferdam seat block

Continuous casting intermediate packages used in the plug rod, seat brick, water mouth refractory quality to determine the plug rod intermediate packages service life, seat brick and intermediate packages used in conjunction with the water mouth, the main role is to fix, protect the intermediate packages of the water mouth, to improve the accuracy of the installation of the mouth of the water mouth, the service life, the plug rod and the intermediate packages of the water mouth with the control of the flow.

In order to solve the problem of uneven and fast erosion of the head of the plug rod in the middle pack of the plug rod, a combined weir seat brick of the middle pack of the plug rod is developed. The combined seat brick is divided into two parts, in which the lower seat brick is used for the positioning of the intermediate package seat brick and the water outlet, and the upper seat brick is higher than the bowl of the intermediate package water outlet with which it cooperates, which plays the role of protecting the bowl of the intermediate package water outlet and the head of the plug rod. Plug rod intermediate package water outlet, plug rod, combined cofferdam seat brick with the solution to the intermediate package steel water on the plug rod head of uneven, too fast scouring, improve the service life of the plug rod intermediate package.

Implementation results

(1)The intermediate package working layer composite masonry process greatly improves the anti-erosion performance of the intermediate package slag line part. After the implementation of the process, observe the use of 48h intermediate package, intermediate package slag line parts of the working layer of erosion disappeared, magnesium carbon bricks shape intact; observe the use of 70h intermediate package, intermediate package slag line parts of the magnesium carbon bricks are still part of the residue, intermediate package turn over the package, check the permanent layer intact.

(2) The middle pack impact area magnesium plate combination masonry process improves the erosion resistance of the middle pack impact area.

After the implementation of the process, observe the use of 48h intermediate package, intermediate package impact zone parts of magnesium carbon plate shape obvious erosion, the working layer is intact; observe the use of 70h intermediate package, intermediate package impact zone parts of magnesium carbon plate disappears, the working layer erosion thickness in 100 ~ 150mm, the number of intermediate packages due to severe erosion of the impact zone in 2019 off the line reduced to zero.

(3)The application of plug rod intermediate pack combined cofferdam seat brick effectively solves the problem of uneven and too fast erosion of plug rod intermediate pack plug rod head, and greatly improves the anti-erosion performance of plug rod head. After the implementation of the process, observe the use of 11h plug rod intermediate package, plug rod intermediate package rod head slightly eroded; observe the use of 18h intermediate package, plug rod intermediate package rod head has obvious erosion, but compared with the optimization of the former significantly lighter, can continue to use.

(4) The application of the new long-life water mouth, reduce the erosion of steel on the zirconium core, the field use of 72h after the intermediate package of the water mouth without blowing phenomenon, the water mouth into the foreign body to reduce to 1 time / month.

Through the application of intermediate ladle slag line magnesium and carbon brick composite repair technology, intermediate ladle impact zone magnesium plate combination repair technology, continuous casting intermediate ladle long-life water spout technology, plug bar intermediate ladle combination of cofferdam seating brick technology, Laiwu Branch Steelmaking Plant intermediate ladle overall resistance to scrubbing improved, impact zone material stability, to ensure the cleanliness of the molten steel and improve the rate of metal yield, sizing intermediate ladle average life increased from 48h / packet to 72h / packet, the average life of the intermediate ladle from 48h / packet to 72h / packet. The average life of sizing intermediate ladle is increased from 48h/ladle to 72h/ladle.