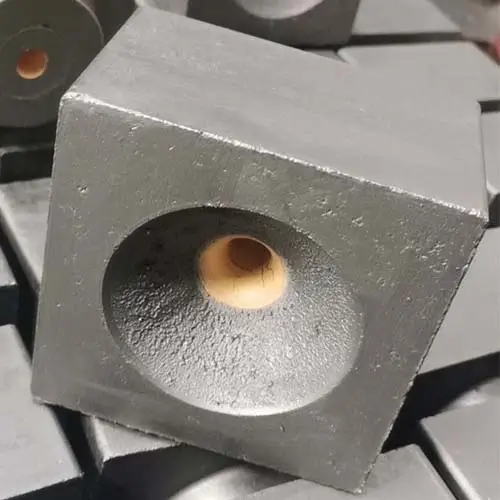

Tundish Well Block Description :

The continuous casting Tundish Well Block,it is a Refractories For Tundish and also a Tundish Nozzle Material for Tundish Nozzle Uses. Seating blocks are made from high-purity, high-density, high-strength materials with a matrix-adjusted system (MAS). These products exhibit the features of stable structure, good corrosion/erosion resistance, excellent thermal shock resistance and long service life.

We produce two kinds of tundish well block: alumina magnesia based and clay based. The alumina magnesia based are unburned block. They have been used in many iron and steel companies with good results.

Tundish Well Block Application:

1. Suitable for tundish well block under different process conditions

2. Can be assort with billet nozzle. changer, common metering nozzle. stopper for slab and slide plate.

What are the advantages of Tundish Well Block?

Tundish well block has high corrosion resistance, good thermal shock resistance and erosion resistance. It’s widely used throughout metallurgical industry. The Tundish Well Block product has good thermal vibration stability and high safety factor.

Tundish well block is made of high-quality raw materials, precision-formed, formed by strong pressure, and dried at low temperature. Tundish well block is used in conjunction with nozzle, mainly used for continuous casting tundish. Tundish well blocks are a refractory precast shape that is used to fill the pocket area of a tundish where each tundish nozzle is inserted.

We strive to create Tundish Refractories Tundish Well Block with reliable performance and customer satisfaction to serve users at home and abroad. Now we have a excellent team supplying specialist service, prompt reply, timely delivery, excellent quality and best price to our customers.

Tundish well block made by Changxing Refractory is mainly in alumina carbon material, and service life can reach as long as 48 working hours in continuous working tundish. The well block can be realized in any size and shape according to nozzle. Changxing supplies nozzles in a number of different compositions to best suit the operating conditions of the steel ladle. Nozzles are available in alumina qualities (with and without carbon additions, zirconia additions, and/or chrome additions) to best resist the slag chemistry. Nozzles are either pressed or pre-cast depending on the composition.

Reviews

There are no reviews yet.