What is Neutral Ramming Mass?

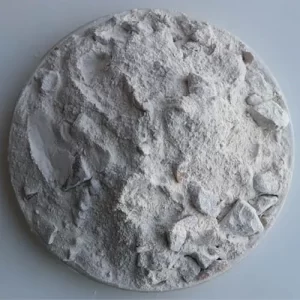

Neutral Ramming Mass is a fused alumina-based dry vibratable refractory designed for lining coreless induction furnaces melting stainless and high-alloy steels. An addition of magnesia provides spinel bonding for high temperature strength. DV932A is best suited for larger coreless furnaces operating at tap temperatures ranging from 1500°C to 1700°C (2730°F to 3100°F). Alumina (Al2O3) is the most fashionable material for producing neutral linings of induction furnaces used in steel industry. This type of lining has very high melting temperature, high strength, high hardness, and relatively high resistance to slag attack. The typical chemical composition of neutral ramming mass is Al2O3 – 86 % to 88 %, MgO – 7 % to 13 %, chromium oxide (Cr2O3) – 4 %, SiO2 – maximum 0.5 %, Fe2O3 – maximum 0.2 %, and TiO2 – maximum 0.2 %. The size fraction of the neutral ramming mass ranges from 0 mm – 5 mm.

We are offering neutral ramming mass, which is featured with rust resistance, wear resistance and thermal stability. This product contains very less binders, moisture content and fire clay. Further, its granulation is optimized considering various standard requirements of its capacity and make. Hence, use of our neutral ramming mass will give maximum benefit along with optimum results. It can also be used for lining the iron melting coreless induction furnace.

Neutral Ramming Mass offers the following benefits and features:

*For continuous or batch melt operations

*Excellent resistance to chemical attack

*Spinel bond for high temperature thermal stability and strength

Backed by our employees and top class management staffs, we have managed to become one of the leading manufacturers and suppliers of Neutral Ramming Mass. It is formulated using top notch quality chemicals that we procure from reliable and authorized vendors only. Offered Neutral Ramming Mass is highly demanded for better quality of lining results, wear resistance, smooth working of furnaces, thermal stability, corrosion resistance, greater metallurgical control and maximum output.

Neutral Ramming Mass Benefit:

Being neutral in nature, it can be used for melting any quality of iron or steel, be it in the presence of either acidic or basic nature of slag.

Lesser number of shutdowns ensures a much less requirement of manpower.

As it is an in-situ spinel forming ramming mass, it is proven to have an excellent thermal shock resistance.

Against silica and other ramming masses it is non-hazardous and nature-friendly.

It has a very low thermal conductivity & coefficient of expansion, thus decreasing power consumption that is upto 10-15 units/ton of molten steel.

With a specific ability of sintering only on the surface, that is in contact with the molten steel, it is able to resist penetration & protrusion of cracks & pores into the refraction lining, thus providing safety from penetration of molten steel towards the heat sensitive crucible & it also ensures easy removal while replacing the lining.

Reviews

There are no reviews yet.