Understanding the reasons for the destruction of the ladle slide plate, let’s have a general understanding of the sliding gate mechanism of the ladle. The schematic diagram of the structure of the spout and slide plate is shown below:

The ladle sliding nozzle is composed of sliding gate mechanism, upper nozzle, slide plate and lower nozzle. Slide plate is divided into upper slide plate and lower slide plate, the shape of the slide plate depends on the required shape of the mechanism, upper and lower slide plate with the same dimensions can be used interchangeably, the size is different, can not be used interchangeably. The ladle upper slide is fixed, the lower slide is movable. There are two types of moving methods: linear reciprocating and rotary.

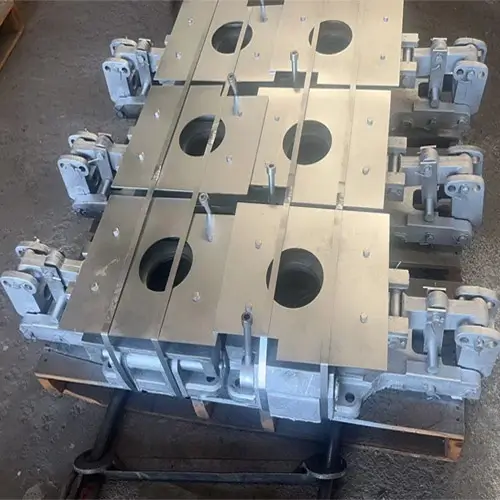

The linear reciprocating sliding gate mechanism usually consists of a reference plate, a fixed frame, a movable frame, and a sliding box. The lower sliding plate is mounted in the sliding box and is pressed by a spring to control the clearance using ladle upper and lower sliding plates. The sliding plate is usually moved reciprocally with hydraulic cylinders and electric actuators to control the flow of steel.

Erosion mechanism of ladle slide plate

Thermo-mechanical corrosion

Ladle slide plate in the use of the process is the first thermo-mechanical corrosion, ladle slide plate in the use of the temperature is very low before pouring, slide plate inner hole suddenly contact with high temperature steel (1600 ℃) and subjected to a strong thermal shock (temperature change of about 1400 ℃), and therefore in the casting of the hole outside of the tensile stress over the strength of the slide plate, leading to the formation of the formation of casting holes as the center of the radial micro-cracks.

The emergence of cracks is conducive to the diffusion of foreign impurities, agglomeration and penetration, and accelerate the chemical erosion. At the same time, the chemical erosion reaction and promote the formation and expansion of cracks, so the cycle, so that the slide cast hole gradually expand, damage. And high-temperature steel scouring will damage and steel friction parts of the refractory material, and cause spalling, falling block.

Thermochemical Erosion

Thermo-chemical erosion is another major cause of slide gate damage. The refractory material for ladle slide plate is exposed to high temperature molten steel and slag in the process of use, and a series of chemical reaction occurs, resulting in chemical erosion. According to different steel types on the chemical damage mechanism of the ladle slide plate is different, and then based on different conditions of use, choose the appropriate material of the ladle slide plate, so as to improve the service life of the slide plate, reduce the cost of refractory materials.

Chemical mechanisms of Al₂O₃-C and ZrO₂-Al₂O₃-C plasma slide damage:

(1) Oxidation of carbon. Graphite and carbon oxidation there are two main ways: one is the oxygen in the steel, especially high-oxygen steel oxidation of carbon and the formation of pores, and then iron infiltration into the pores and make the surface of the ladle slide plate adhering to the steel; the second is the oxygen in the air oxidation of carbon and steel, the generation of low-melting material, low-melting material along the pores to continue the erosion of the infiltration.

(2) Mullite decomposition. Mullite in the use of varying degrees of decomposition, into columnar and crystalline corundum crystals, the formation of porous structure, the destruction of the original mullite and plagioclase composed of dense eutectic structure, so that the structure of the loose, organization deterioration, strength and corrosion resistance greatly reduced, accelerating the destruction of the slide.

(3) (Mn), (Fe) erosion of the ladle slide plate. SiO₂ in the ladle slide plate reacts with FeO and MnO in the steel and slag to form the low melting point mineral phases 2FeO-SiO₂( 1205°C), MnO-SiO₂( 1291°C).

(4) (Ca) damage to the slide. Al₂O3-SiO₂ reacts with CaO in the steel and slag to form the low-melting-point 2CaO-Al₂O₃-SiO₂( 1327°C) and 12CaO-7Al₂O₃( 1392°C).

The effect of operational factors on ladle slide gate

There are three main damage factors to the slide gate plate by operating factors.

First, the installation of the ladle slide plate is unreasonable. When the ladle slide plate is installed to the sliding gate mechanism, if there is warping or clamping looseness, it will produce a great deal of external stress in the process of use, which will eventually lead to the overall destruction of the slide gate plate.

Second, the production of casting flow control is unreasonable. In the casting process if the flow control is unreasonable (for example, the operation amplitude is too large, the action is too frequent, etc.), it is easy to lead to the slip of the working surface of the ladle slide plate, erosion, clamping steel and other sites. Especially manual when the human factor on the ladle slide plate caused by the damage is the biggest.

Third, the oxygen burning operation is unreasonable. Ladle in the pouring process is not downstream, are to burn oxygen to the ladle water mouth, this time if the burning oxygen operation is unreasonable, will produce serious burning oxygen erosion.

This middle of the improper operation is mainly ① ladle slide plate is not completely eye to eye that blowing oxygen, resulting in direct impact of oxygen on the working surface of the slide plate; ② diversion sand is not completely out of the hard to burn, then blowing oxygen is easy to cause blowing oxygen time is too long; ③ oxygen pipe and the flow of the production is not parallel, resulting in the oxygen flow of the slide plate hole scouring the side wall, the formation of the expansion of holes, and so on. ④ When the turnover time of the ladle is unreasonable, the overall temperature of the ladle will drop, and then the thermal shock caused by the use of the ladle; ⑤ The fire clay used in the ladle slide plate is improperly proportioned, unevenly stirred, or there are impurities in it.

Ladle slide gate plate in the use of the process of repeated contact with high-temperature molten steel, the use of harsh conditions, so it is required that the ladle slide plate has the following properties to ensure that the casting process between the ladle slide plate does not leakage of molten steel, its structure and performance to meet the general:

(1) Smooth sliding surface and good flatness.

(2)High mechanical strength.

(3)High erosion resistance to steel and slag.

(4) Not easy to adhere to molten steel.

Through the practice of some measures to improve the longevity of the slide plate, specific as follows:

First of all, the material of the ladle slide plate, generally choose to corundum, mullite, oblique zirconia as the main crystalline phase, carbonaceous material as the binding agent of the material, the advantages of this type of material is the thermal conductivity is large, the coefficient of thermal expansion is small, heat shock resistance.

In the installation process of the ladle slide plate, also pay attention to the upper and lower water outlets cleaned up, the slide plate frame and the mechanism of the door needs to be cleaned up, there can be no residue. The slide plate can not be used if there is deformation, cracking and other unevenness.

The ladle is strictly prohibited from blowing oxygen cleaning from the inside to the outside when replacing the water outlet. Oxygen cleaning speed should be fast, if found abnormal conditions need to replace the ladle slide plate.