Converter steelmaking is currently one of the most widely used steel production methods globally. It has become the mainstream approach due to its high efficiency, short smelting cycle, low production costs, and adaptability to various steel grades. Statistics show that converter steelmaking accounts for over 70% of the world’s total crude steel production. In China, this proportion exceeds 90% of crude steel output. According to data from the China Iron and Steel Association (CISA), as of 2017, China had 547 operational steelmaking converters with a total production capacity of 688.91 million tons. In terms of scale, 14 converters have a capacity of 300 tons or more, while converters with 100-ton capacities or larger already constitute over 60% of the total. With the nation’s continuous efforts to phase out outdated production capacities, China’s converter steelmaking industry is further advancing toward large-scale development.

In recent years, great progress has been made in converter steelmaking technology. Top and bottom combined blowing technology and slide plate slag blocking technology have appeared successively. In particular, the emergence of top and bottom combined blowing technology has significantly shortened the smelting time, and the composition and temperature of the molten steel have been more uniform. At the same time, the content of S, P and N elements in the molten steel has been reduced, and the metal yield has been improved. However, with the increase of converter re-blowing ratio, the converter life is significantly reduced, as shown in Figure 2. In order to increase the service life of the converter, there is a method of regularly repairing the front and rear large surfaces with self-flowing repair materials and spraying the ear shafts and other parts. If this maintenance method is used and repaired in time, the life of the furnace lining can be extended to more than 8,000 times. The method of slag splashing is often used to protect the furnace. That is, some light-burned magnesium balls or dolomite are added into the furnace to increase the melting point and viscosity of the slag, and the slag is splashed onto the furnace lining by high-pressure nitrogen. The life of the furnace lining can be as high as more than 20,000 furnace times. However, this method consumes a lot of nitrogen and has a high heat loss. Slag splashing is required once for each furnace, which affects the steelmaking efficiency. In addition, the converter bottom gas supply components (air-permeable bricks) have a short service life, which affects the combined blowing effect. Sliding gate slag blocking technology has become a new mainstream of development due to its advantages of reducing rephosphorization of molten steel, improving alloy recovery rate, reducing inclusions in steel, and improving the cleanliness of molten steel. However, the sliding nozzle system, especially the slag retaining slide plate, is easily damaged and its service life needs to be improved. Under the new smelting technology conditions, there are many problems with refractory materials used in steelmaking converters, which has attracted great attention from relevant researchers. A lot of research and exploration work has been carried out to target the new demands for converter refractory materials, and many new refractory technologies have emerged.

1.Main types of steelmaking converters and smelting processes

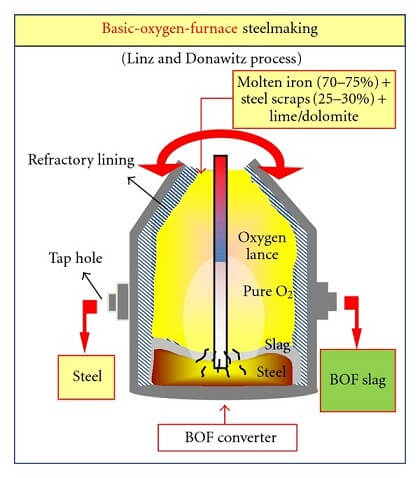

According to the properties of the refractory materials of the lining, converters can be divided into acid converters and alkaline converters; according to the position where the gas is blown into the furnace, converters can be divided into bottom blowing, top blowing, side blowing and top and bottom combined blowing converters; according to the type of gas, converters can be divided into air converters and oxygen converters. Basic oxygen top-blown and top-bottom combined-blown converters have become the most commonly used steelmaking equipment due to their fast production speed, large output, high single-furnace output, low cost and low investment. Converters are mainly used to produce carbon steel, alloy steel, etc.

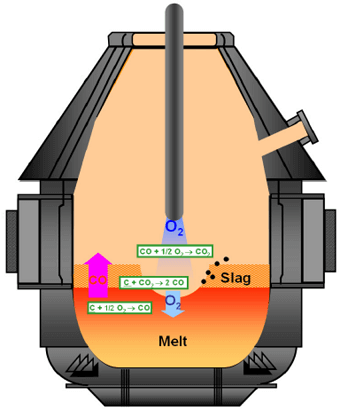

Converter steelmaking uses molten iron, scrap steel, and ferroalloys as main raw materials, adds a small amount of quicklime, and blows in air or oxygen to oxidize impurities such as silicon, manganese, phosphorus, sulfur, and carbon. During the oxidation process, a large amount of heat is released (1% (w) silicon can increase the temperature of pig iron by 200°C), which can make the furnace reach a sufficiently high temperature (without the help of external energy). The steelmaking process is completed in the converter by relying on the physical heat of the molten iron itself and the chemical reactions between the components of the molten iron to generate heat.

2.Refractory materials for steelmaking converters and their damage mechanisms

The refractory materials used for the lining of steel-making converters are mainly MgO-C bricks, with a small amount of high-purity magnesia bricks and magnesia dolomite fired bricks. The amorphous refractory materials used include MgO-SiO2, MgO-C, MgO-CaO, high-purity MgO, etc.

During the converter steelmaking process, the furnace lining is corroded by a series of strong mechanical, physical and chemical effects. The converter double blowing process is to install air bricks at the bottom of the converter and blow oxygen, carbon dioxide, argon or nitrogen into the furnace through the air bricks, which strengthens the stirring of the molten pool and improves the smelting reaction. This shortens the steelmaking time, improves the quality of molten steel and reduces the cost of steelmaking. However, combined blowing also accelerates the erosion of the refractory materials of the furnace lining, and different parts of the converter are subject to erosion under different conditions.

(1) Scouring or mechanical impact. Operations such as adding scrap steel and adding molten iron are directly directed to the large-surface lining of the converter, which causes strong impact, wear and scouring to the large-surface lining, and is the main factor in the erosion of the lining resistant material. During the smelting process, there are physical erosions such as the scouring of furnace walls, furnace caps and other refractory materials by the airflow in the furnace, the melting and scouring of the furnace lining by molten steel and slag, and the melting loss of the furnace lining by high-temperature reactions during the smelting process.

(2) Oxidation and chemical corrosion. Oxidation is a major cause of corrosion of magnesia carbon bricks in converter linings. During this process, the carbon component in magnesia carbon bricks is oxidized by oxygen-containing components (such as high-temperature oxidizing gases, iron oxide, oxygen, and magnesium oxide), causing the material structure to loosen and become brittle.

FeO+C(s)=Fe+CO(g), (1)

O2(g)+2C(s)=2CO(g), (2)

MgO(s)+C(s)=Mg(g)+CO(g)。(3)

The iron oxide in the slag reacts with the graphite or tar/resin in the hot side of the brick lining, or the oxygen attacks the graphite or binder on the cold side of the brick lining. In both cases, the strength of the brick is reduced and it is lost and corroded under the scouring of gas and molten metal fluids.

The chemical reaction between iron oxide (FeO) or acidic components in slag, such as SiO2, and CaO and MgO is shown in the following equation:

FeO+MgO=FeO·MgO, (4)

SiO2+2MgO=2MgO·SiO2,(5)

CaO+SiO2+MgO=CaO·MgO·SiO2。(6)

All of the above reactions can turn the furnace lining into slag, thus causing damage to the refractory material.

(3) Thermal shock peeling. The working environment of the air supply component is high pressure and large flow (pressure greater than 1MPa, flow rate 0.15~0.2m3·min-1·t-1), and its damage mechanism is spalling and erosion wear caused by thermal stress concentration.

(4) Abrasion, melting and spalling. During the steel-making process of the converter, the sliding nozzle and the slide plate must withstand the scouring of high-temperature molten steel and steel slag; the erosion and penetration of strongly alkaline slag; and intermittent high-temperature (~1600℃) strong thermal shock. In addition, during the slag blocking operation, the slide plate has to withstand the abrasion of the slag.

Therefore, the main damage modes are the scouring and erosion of high-temperature molten steel and steel slag, high-temperature oxidation, roughening and abrasion of sliding surfaces, and thermal shock damage. The future technical direction of steelmaking converter refractory optimization is:

(1) Develop high-performance wear-resistant and thermal shock-resistant low-carbon magnesium carbon bricks;

(2) Develop fast-sintering, pollution-free hot repair materials and long-life gunning materials;

(3) Develop long-life combined blowing gas supply components, optimize the structure and layout of the furnace bottom tuyere, and adapt to the requirements of advanced steelmaking technologies such as top and bottom combined blowing, low-oxygen steelmaking, bottom blowing powder injection, bottom oxygen supply, and bottom blowing CO2;

(4) Improve the performance and structure of the slag retaining slide, extend its service life, and reduce the number of daily replacements.

3.New technology of refractory materials for steelmaking converter

3.1 Development and application of high performance lining bricks

Magnesia carbon bricks are widely used as lining bricks for converters due to their excellent resistance to slag erosion, thermal shock resistance, spalling resistance, wear resistance, and good stability at high temperatures. Since magnesium carbon bricks are easily oxidized, resulting in poor thermal shock resistance and corrosion resistance, researchers have conducted extensive exploratory research. Its key technical hotspots are reflected in:

1) The application of new anti-oxidation and self-repairing composite antioxidants: using metal Al, Si powder, or Al-Si composite powder as antioxidants for magnesia carbon bricks, which react in situ during heat treatment or high-temperature service to generate highly corrosion-resistant phases such as SiC and AlN, significantly improving the performance of low-carbon magnesia carbon materials.

2) Preparation and application of low-dimensional graphitized carbon: Addition and application of various pre-synthesized nanocarbons such as nano-carbon black, nano-graphite-oxide composite powders, etc.; in-situ synthesis of low-dimensional graphitized carbon, selection of inorganic or organic compounds of suitable transition elements (Fe, Co, Ni) as catalysts, phenolic resin cracking to produce gases such as CO, C2H2 and CH4, which form low-dimensional graphitized carbon such as carbon nanotubes and nano-carbon fibers under the catalysis of transition metals. Through the development and application of these new technologies, MgO-C bricks maintain good corrosion resistance and thermal shock resistance.

The MgO-C bricks used in different parts of the converter have different requirements for their performance. In order to meet the needs, Japan Shinagawa Refractory Co., Ltd. has developed a series of MgO-C bricks that meet the performance requirements of different parts. Their basic performance and typical characteristics are shown in Table 2. The microstructural analysis of the used MgO-C bricks shows that the damage of the MgO-C bricks is mainly manifested as slag erosion damage. Japanese researchers studied the damage factors of MgO-C bricks and found that limiting the diffusion rate of Mg(g) in MgO-C bricks at high temperatures can reduce the damage rate of bricks. The results of the slag corrosion resistance test show that with the increase of the apparent porosity of MgO-C bricks (heat treated at 1500℃), the corrosion index of the bricks increases linearly. Based on this, dense structure MgO-C bricks were prepared by adjusting the amount of antioxidant added, raw material particle grading and production process.

The MgO-C bricks in the converter charging area are often subjected to mechanical impact from scrap steel raw materials, which can easily cause cracks and expand, leading to damage to the lining. Different types of MgO-C bricks have very different creep resistance, as shown in Figure 5[3], which leads to differences in the thermal shock resistance and mechanical impact resistance of MgO-C bricks. Researchers from Shinagawa Refractory Co., Ltd. in Japan found that MgO-C bricks (HS) with higher high-temperature flexural strength cannot alleviate the occurrence of damage, while MgO-C bricks with higher fracture energy (fracture toughness) can effectively inhibit the expansion of cracks. Therefore, two new types of MgO-C bricks, namely matrix-reinforced MgO-C bricks (MR) and carbon-bonded reinforced MgO-C bricks (CB), were developed. The properties are shown in Table 2. The two new types of MgO-C bricks have higher fracture energy (MR 0.40kJ and CB 0.49kJ, HS only 0.26kJ), crack propagation is suppressed after mechanical impact, and both have better corrosion resistance than HS bricks, among which the carbon-bonded enhanced MgO-C bricks have better corrosion resistance.

The service life of magnesia carbon bricks at the converter outlet is often affected by carbon oxidation, thermal shock spalling and flow steel wear. Therefore, the development of low-carbon magnesia-carbon bricks with good wear resistance and thermal shock resistance is an inevitable trend of development. Researchers at the Second Steel Plant of TISCO used fused magnesia with m(CaO):m(SiO2)≥2 and high-purity flake graphite (C mass fraction ≥98%) as the main raw materials, Al, Mg-Al, Si, B4C, CaB6 as antioxidants, and thermosetting phenolic resin as a binder to prepare high-quality low-carbon MgO-C bricks. The properties are shown in Table 3. The newly developed low-carbon magnesia-carbon bricks are used in steel-making converters, and the service life of a furnace is stabilized at 500~700 times, which is a significant improvement over the 300~400 times of imported low-carbon magnesia-carbon bricks.

3.2 Development and application of monolithic refractory materials

Due to the increase in the amount of scrap steel used in steelmaking and the application of new top and bottom blowing technology, the operating conditions of the converter have become more harsh and the damage of refractory materials has accelerated. In order to increase the service life of the converter, higher requirements are placed on the refractory materials used in various parts of the converter. The development of new amorphous refractory materials and the application of repair technology have been greatly developed, which can greatly improve the overall service life of the furnace lining without affecting normal production, and make the furnace lining life reach more than 8,000 times, or even more than 20,000 times. At present, large-surface hot repair materials are generally used to maintain the charging side, furnace bottom and steel-tapping side of the converter, gunning materials are used to maintain the molten pool, fillet and ear shaft of the converter, and grouting materials are used for filling the gaps when replacing the converter steel-tapping port and maintaining the steel-tapping port area. Among them, the main large fabrics are MgO-SiO2 (also known as water-based large fabrics), MgO-C, MgO-CaO, etc., and the main gunning materials are MgO, MgO-CaO and MgO-Cr2O3. These amorphous refractory materials are divided into anhydrous repair materials (mainly asphalt, coal tar and asphalt powder, phenolic resin combination) and water-based repair materials (MgO-SiO2-H2O combination and phosphate combination) according to the different binders. The performance of repair materials with different binding systems has their own advantages and disadvantages. In view of the shortcomings and application requirements of existing repair materials, researchers have conducted extensive research and developed large-surface or spraying materials with better performance.

The large-surface converter repair materials currently used for on-site repairs mainly use coal tar, asphalt (about 8%~15% (w)), resin and other organic substances as binders. There are inevitably some problems, such as: the sintering time is too long, and the material has many pores and poor density after the organic matter is burned out, which leads to inresistance to slag erosion, low strength, short service life, and serious pollution of the on-site workshop environment. Qin Yan et al. [16] selected high-purity magnesia powder (w(MgO)=97.02%) and medium-grade magnesia particles (w(MgO)=94.80%) as the main raw materials, and ultrafine silicon oxide powder (w(SiO2)=96.0%) as a binder to develop a new type of long-life carbon-free and environmentally friendly converter large surface repair material.

The environmentally friendly water-based converter large surface repair material does not produce harmful gases during the sintering process and is safe and environmentally friendly. The product adopts the wet self-flowing pouring method, has excellent high-temperature spreading performance, and forms a ceramic bond after high-temperature sintering. It has a dense structure, is anti-oxidation, and is resistant to erosion. The volume density can reach 2.83g·cm-3. After being used by many converter steelmaking users, it is smokeless when used on site, the sintering time is shortened by more than 50% compared with conventional carbon-based large fabrics, and the service life is extended by 2 to 3 times.

Due to the continuous impact of mechanical force and erosion of slag, the refractory materials on the bottom, ear shaft and two major surfaces of the oxygen top-blown converter are easily damaged, and it is necessary to frequently repair the ear shaft and slag line by spraying. The most commonly used converter gunning material in China is magnesium gunning material. In order to improve its shortcomings such as lack of corrosion resistance, lack of erosion resistance and short service life, Yao Yashuang et al. [22] developed a new type of converter magnesium-carbon gunning material. The raw materials used for the gunning material are mainly 3-0mm magnesia (w(MgO)=95.2%), 3-0mm carbon (w(C)=94.2%), asphalt A (fixed C46.2%, softening point 140-160℃), asphalt B (fixed C43.5%, softening point 100-120℃), additives, etc. Carbon and asphalt B are mixed in different proportions as the carbon source of the gunning material, and the mass fraction of fixed carbon is about 5% to 7%. The test shows that asphalt B has a larger particle size, so its heating and carbonization speeds are slower, and its carbonization degree is higher, which is more beneficial to the adhesion of the gunning material. Among them, the gunning material with a carbon to asphalt mass ratio of 7:2 has the best performance, greater strength after burning and better corrosion resistance. The results of use show that the new type of converter magnesium-carbon gunning material has a low rebound rate, good adhesion and high sintering strength; the service life of the original magnesium gunning material is 7 to 8 furnaces, while the service life of the new type of magnesium-carbon gunning material is 10 to 13 furnaces, which is increased by more than 30%, greatly shortening the number of converter repairs.

In order to solve the problem of slag sticking on the slag surface of the converter furnace mouth and furnace cap, Zhu Shanhe and others developed a converter anti-slag spraying material with recycled magnesia carbon bricks as the main raw material. The application results show that the developed anti-slag gunning material has good construction performance. Through semi-dry gunning construction, a complete and uniform slag isolation spray layer can be formed on the surface of the converter furnace mouth. The thickness of the spray layer can reach 35-50mm, and the spray adhesion rate can reach more than 80%. Only one gunning is required per shift to meet the slag isolation needs; the thick gunning layer itself and its bonding strength with the gunning surface are low, which reduces the difficulty of peeling and cleaning the sticky slag, reduces the number and time of cleaning the sticky slag, effectively improves the cleaning efficiency of the converter furnace mouth sticky slag, and shortens the non-production operation time; without changing the production process, the converter production capacity can be improved.

Japan’s Shinagawa Refractory Co., Ltd. has developed a fast-hardening MgO-C converter hot repair material. The developed carbon-bonded MgO-C gunning material has good adhesion even when gunning to brick surfaces above 1300°C after slag removal. It can significantly improve the hot repair efficiency of the converter, can be constructed at ultra-high temperatures, and greatly shortens the hardening time, which helps to shorten the repair time.

3.3 Top and bottom blowing technology

The converter composite blowing process uses bottom blowing gas to stir the molten pool to make the slag reaction close to equilibrium, avoid overoxidation of molten steel and improve metal yield and molten steel quality. The converter bottom gas supply components are divided into two categories: nozzle type and brick type. Among them, brick-type air supply components have become the mainstream direction of development due to their stable performance. Brick-type air supply components mainly include three types: diffuse type, annular gap type and straight-through hole type. Dispersed air bricks have disadvantages such as large gas bypass resistance and low lifespan; annular seam air bricks are relatively dense and have a longer lifespan than dispersed bricks. They are widely used and well received, but their stability is far inferior to that of straight-through hole air bricks. Therefore, straight-through hole air bricks will be the new mainstream in the development and application of air supply components in the future. Optimizing its position at the bottom of the molten pool is crucial to achieving good metallurgical effects of bottom blowing. The currently widely used straight-through hole type gas supply component (Multiple Hole Plug, referred to as MHP) was first developed by Japan Steel Pipe Company. Its advantages are small gas supply resistance, large gas flow adjustment range, good air tightness, and no leakage; the metal pipe strengthens the refractory bricks so that the bricks are not easy to peel off or crack.

In order to optimize the performance of the gas supply element, the proportion of refractory raw materials used to manufacture the gas supply element is adjusted and the internal stainless steel pipe is specially treated, which greatly improves its service life and increases its matching degree with the converter life. Zhang Yueming used high-purity fused magnesia (w(MgO) ≥ 97%) and natural flaky graphite (w(C) ≥ 98%) as the main raw materials, added Al, Si powder and B4C (total amount < 6%) as antioxidants, selected thermosetting and asphalt-modified resins as binders, and added an appropriate amount of asphalt powder, and prepared high-performance MgO-C gas supply components by isostatic pressing. The prepared MgO-C gas supply component has significantly improved oxidation resistance, fracture toughness and thermal shock resistance, good air tightness, an erosion rate of 0.28mm/heat, and a maximum lifespan of up to 2113 heats. In order to reduce the carburizing rate of stainless steel pipes and increase their service life, the method of coating the surface with α-Al2O3/ALCH slurry was adopted, and the ratio of α-Al2O3/ALCH was controlled to be greater than 3/7, and the coating thickness was greater than 1mm, so that a dense protective isolation layer with stable thermal properties and resistance to carbon reduction was formed on the surface of the stainless steel pipe.

The refractory bricks used in converter gas supply components have a large temperature difference between the inside and outside, which increases the temperature gradient difference inside the refractory bricks; in addition, the temperature drops sharply after steel is tapped, and the air-permeable bricks are subjected to a great degree of thermal shock. Due to the existence of these thermal stresses, cracks are generated and expanded inside the air-permeable bricks, causing intermittent spalling of the refractory bricks. Researchers at Shinagawa Refractory Co., Ltd. found that the cracks produced in breathable bricks are mainly cracks parallel to the hot surface, and the damage caused by thermal spalling is far more serious than the damage caused by factors such as erosion by molten steel and wear. Based on a thorough investigation of the damage mechanism of breathable bricks, high-performance breathable bricks with high fracture toughness and excellent thermal shock resistance have been developed. The specific properties are shown in Table 7. First, by improving the toughness of the material, the generation and expansion of cracks are inhibited, greatly reducing spalling damage. Secondly, by increasing the size of the breathable bricks to extend the distance that the crack extends to the spalling surface, the occurrence of spalling is effectively reduced. When used in a 220t converter, the loss rate is reduced by about 40% compared with traditional breathable bricks, and the spalling damage is improved. The converter has been running for more than 4,000 furnaces without replacing the breathable bricks.

3.4 Slide plate slag blocking technology

The converter slide slag blocking technology is an emerging technology that has developed rapidly in recent years. This technology is mainly composed of three parts: slide slag blocking system, infrared slag detection system and hydraulic drive system. By combining infrared slag detection technology with PLC control technology, automatic slag judgment and slag blocking can be achieved. It is currently the best and latest production process technology and equipment for converter steelmaking slag blocking. The sliding gate slag blocking technology has outstanding advantages in reducing the rephosphorization of molten steel, improving the alloy recovery rate, reducing inclusions in steel, improving the cleanliness of molten steel, reducing slag sticking to the ladle, and extending the service life of the ladle.

The inner water inlet of the converter tapping port is connected to the end of the tapping port brick and is connected to the upper slide plate of the tapping port below, while the outer water inlet is connected to the lower slide plate of the tapping port. Therefore, during the converter tapping process, the inner/outer nozzles and slide plates must not only withstand the scouring of high-temperature molten steel and steel slag, but also the erosion and penetration of strongly alkaline slag; during discontinuous tapping, they must also withstand strong thermal shock of high temperature (~1600℃). In addition, during frequent slag blocking operations, the casting holes and slideways of the slide plate have to withstand the abrasion and melting loss of high-temperature molten steel and slag. Therefore, the selection of materials for internal/external nozzles and slide plates should focus on good slag erosion resistance, high temperature oxidation resistance and excellent thermal shock resistance. The slide plate material should also have excellent wear resistance.

At present, the materials of the external nozzle of the converter tapping port on the market mainly include unburned magnesium carbon, unburned aluminum zirconium carbon and zirconia (inlaid inner core). Among them, magnesium carbon nozzle occupies the mainstream market due to its cost advantage. The performance of aluminum zirconium carbon nozzle is slightly better than that of magnesium carbon. The inlaid zirconia inner core nozzle is in the research and development stage, and its service life can reach more than 120 furnaces, and can even be synchronized with the life of the tapping port. Most of the non-fired water inlets are treated with asphalt impregnation to seal the pores, improve density and corrosion resistance, and their service life ranges from 30 to 90 furnace times.

The slag retaining slide plate is one of the most critical components in the application of sliding gate slag retaining technology. At present, the material of the slag-blocking slide plate in China is mostly aluminum-zirconium-carbon. As the material of the flow control slide plate, it has high strength, good thermal shock resistance, excellent erosion resistance and corrosion resistance; but for the slag-blocking technology, the service life of the slide plate is relatively low, and can only be stable at about 10 to 14 furnaces. Therefore, researchers have improved the performance of the slag retaining slide through various approaches. Studies have shown that the introduction of expanded graphite and Si powder can promote the formation of SiC whiskers in aluminum-carbon refractory materials to a certain extent, improve the toughness of the skateboard, enhance the ability to resist crack propagation, and improve the thermal shock resistance and service life of the skateboard.

In order to meet the high life requirements of 18 to 20 heats or even more than 25 heats proposed by steel companies, the material of the skateboard is transformed from conventional heavy-burned aluminum-zirconium-carbon to a composite structure with aluminum-zirconium-carbon for the main body and zirconium material for the inlay layer. Currently there are mainly three categories: ① an upper slide plate inlaid with zirconium rings and a lower slide plate inlaid with zirconium plates; ② an upper slide plate inlaid with zirconium plates and a lower slide plate inlaid with zirconium plates; ③ an upper slide plate inlaid with zirconium rings and a lower slide plate inlaid with zirconium plates in the anti-slip area of the slide. The service life of the inlaid slide plate on a 120-300t converter (front and rear slag blocking) can be stabilized at at least 15-18 heats. If other slag blocking methods are used in the early slag blocking and only the slide plate is used in the later slag blocking, the service life of the slide plate can reach 20-25 heats.

The disadvantage of the sliding nozzle slag blocking technology is that the life of the refractory components is relatively short. To this end, Interstop cooperated with RHI to improve the traditional steel casting system and developed a new CG120 sliding nozzle for the steelmaking converter tapping port. The CG120 sliding gate system adopts a brand-new structure, which allows the inner slide to be replaced without removing the entire sliding gate device from the steel shell. The system improves the use of refractory materials and significantly shortens converter downtime. The service life of the upper connecting components of the CG new sliding nozzle is 24.8 furnaces, and the service life of the refractory components is 24.8 times.

Sinosteel Luoyang Refractories Research Institute summarized the reasons for the damage of the converter slag stop slide and found that the upper slag stop slide was in contact with the molten steel, which was mainly damaged by erosion and hole expansion, while the lower slide was in contact with the outside air, which was mainly damaged by thermal shock crack expansion. Therefore, by inlaying zirconium rings on the upper slide and zirconium plates on the lower slide, and through measures such as phase composition control and microstructure regulation, the thermal shock resistance of zirconium rings and zirconium plates is improved, the life of the slag-blocking slide is stabilized at about 20 heats, and the cost-effectiveness of the slide slag-blocking is significantly improved. The three series of products developed can meet the needs of different working conditions.

By continuously improving and optimizing the appearance and structure design of the slide plate and the inlay structure design, increasing the locking force of the slide plate’s expansion and deformation under high temperature, preventing the occurrence and expansion of abnormal cracks, and preventing the formation of abnormal leakage steel channels; increasing the accuracy of the infrared slag detection system and the stability of the hydraulic drive device cylinder operating speed, focusing on solving the deficiencies found in the application, and greatly improving the safety and reliability of the slide plate slag blocking technology.

Advances in steelmaking technology have promoted the development of new technologies for steelmaking converter refractory materials. The refractory materials involved in the new technology not only have the characteristics of stable high-temperature structure, anti-stripping, wear resistance and good slag resistance, but also embody the development concept of energy saving, long life, low carbon and environmental protection. The future development trend of refractory materials for steelmaking converters is: 1) Develop and promote high-performance magnesium-carbon refractory materials; 2) Promote and apply new environmentally friendly amorphous refractory materials and high-temperature repair technology; 3) Develop new composite structure refractory materials, such as composite gas supply elements, composite slide plates, etc.; 4) Research and develop lightweight, energy-saving refractory materials with good high-temperature performance.