Electric Stove

The electric furnace steelmaking method mainly utilizes electric arc heat, and in the electric arc action area, the temperature is as high as 4000℃. Smelting process is generally divided into melting period, oxidation period and reduction period, in the furnace can not only cause oxidizing atmosphere, but also can cause reducing atmosphere, so the efficiency of dephosphorization and desulfurization is very high.

Electric furnace steelmaking with scrap as raw material, less infrastructure investment than the blast furnace converter method, and at the same time, due to the development of direct reduction, for the electric furnace to provide metallization pellets instead of most of the scrap, so it greatly promote the electric furnace steelmaking.

At present, the domestic go intermediate frequency furnace is more, mainly used for smelting high-quality steel, alloy steel and stainless steel steel, belongs to the smelting of stainless steel, the first production process, the main role is to chemical steel and dephosphorization, desulfurization.

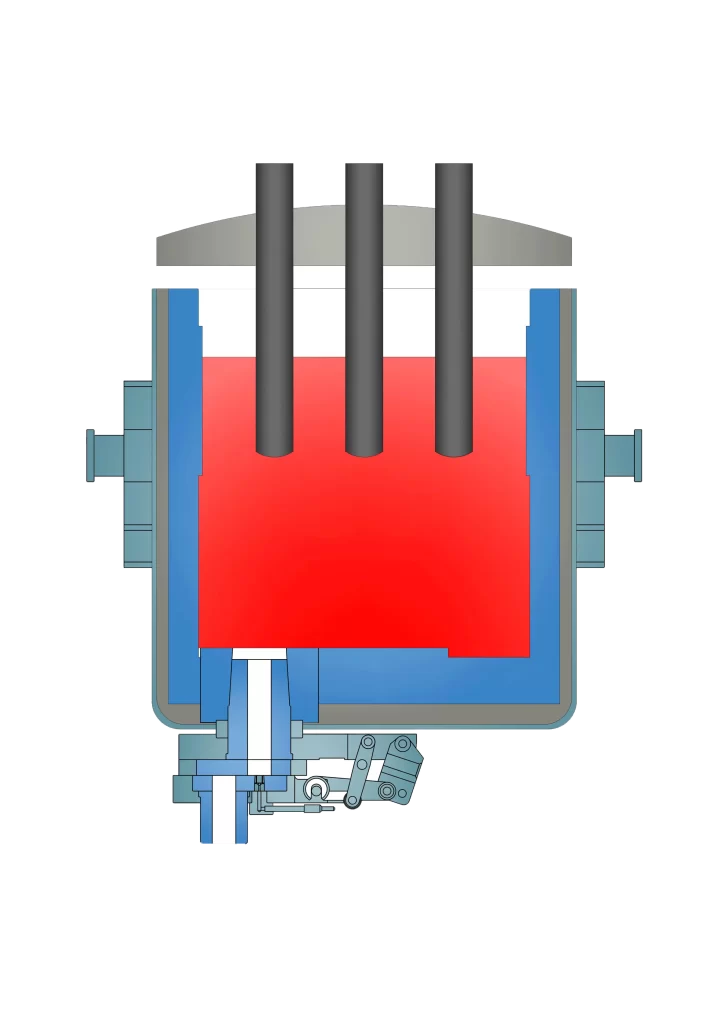

AOD Furnace

AOD furnace method (i.e. argon oxygen decarburization method) is a more advanced technology for refining stainless steel. It has the advantages of simple equipment, convenient operation, strong adaptability, investment savings, low production costs, etc., and is widely used.

Blast furnace molten iron and electric furnace molten steel, injected into the AOD furnace through the ladle, smelting blowing O2, Ar or N2 gas mixture, decarburization of molten steel, and at the same time by the charging system to add reductant, desulfurizing agent, ferroalloys, or coolant to adjust the composition of the molten steel and temperature, smelting qualified stainless steel materials.

Principle: The transportation and adjustment of gas mixture during refining is one of the main systems of argon oxygen furnace. The gas produced by the oxygen workshop is transported into the storage tank near the workshop through the pipeline respectively, and is measured, depressurized, regulated, mixed, and finally the mixed gas with the required flow rate and proportion according to the process is sent into the furnace through the side gun.

At the beginning of smelting, oxygen is blown into the molten metal pool for decarburization through the double-layer water-cooled oxygen blowing pipe from the top furnace opening. Refining is carried out with a gas mixture fed into the furnace by means of a side lance (mounted on the side wall opposite the outlet side, near the bottom of the furnace). When charging and discharging the steel, the furnace body is tilted forward at a certain angle and the (side) air opening is above the liquid steel surface. During normal blowing, the wind mouth sinks into the deep part of the dissolving pool. The center tube of the wind mouth is blown into the mixture of oxygen and argon or nitrogen, and the partial pressure of carbon monoxide can be reduced by adjusting the ratio of oxygen and argon to achieve the purpose of decarburization and chromium preservation.The type of the wind mouth of the AOD furnace is unique, and it is a gas-cooled consumption type wind mouth. The air outlet adopts double casing structure, the outer tube only passes argon or nitrogen to cool the air outlet, and the inner tube passes oxygen and nitrogen, or argon gas mixture. Flow control through the air vent hood ring for optimal operation, the center tube of the air vent hood ring and the flow of the air vent hood ring can be controlled in the main control room.

Three side lance technology is adopted. It can enhance the strength of oxygen supply to improve the metal material yield, and this technology can shorten the AOD smelting time. Stable and reliable control system can reduce the consumption of gas and all kinds of raw materials in smelting and get stable product quality.

Role:

The main role of AOD is to remove carbon and play a role in refining.

Ladle Refining Furnace

LF furnace (LADLE FURNACE), i.e. ladle refining furnace, is the main off-hearth refining equipment in steel production.LF furnace generally refers to the refining furnace in the steel industry. It is actually a special form of electric arc furnace.

LF furnace refining mainly rely on the barrel of white slag, in a low-oxygen atmosphere (oxygen content of 5%), to the barrel blowing argon for stirring and by the graphite electrode after the initial refining furnace steel heating and refining. Due to argon stirring to accelerate the chemical reaction between slag a steel, with electric arc heating for temperature compensation, can ensure a longer refining time, which can make the oxygen and sulfur content in the steel to reduce inclusions according to the ASTM rating of O ~ O. 1. LF furnace can be used in conjunction with the electric furnace to replace the reduction period of the electric furnace, but also can be used in conjunction with the oxygen converter, the production of high-quality alloy steel. In addition, LF furnace is also continuous casting workshop, especially alloy steel continuous casting production line indispensable to control the composition, temperature and preservation of molten steel equipment. Therefore, the emergence of LF furnace formed the LD-LF-RH-CC (continuous casting) new production of high-quality steel joint production line. In this joint production line on the steel reduction and refining is mainly by the LF furnace to complete the LF furnace to deal with the steel almost involved in the steel from special steel to all kinds of steel, the production of depending on the needs of the quality control, the use of different technology operation system. In various secondary refining equipment, the LF furnace has a high overall price ratio.

LF has the following characteristics:

①Desulfurization

②Temperature adjustment

③Precise composition fine-tuning

④Improvement of molten steel purity

⑤Slag making

It mainly has the following functions:

(1)LF furnace is connected with electric furnace to speed up the production cycle of electric furnace and improve the quality of electric furnace steel.

(2) LF furnace is connected with LD converter, which can reduce and refine the converter steel, so it can improve the steel quality and produce new steel grades.

This can improve steel quality and produce new steel grades.

(3) LF furnace can strictly regulate the composition and temperature of liquid steel, which is favorable to the hardenability of steel and continuous casting of special steel.

After AOD refining and then to the LF furnace refining, belongs to the second refining, inclusions reduce to ensure the purity of steel;

VD Vacuum Furnace

VD refining method, is the electric furnace, converter of the initial refining of liquid steel in a closed tank vacuum, while the bottom of the ladle blowing argon stirring a liquid steel vacuum treatment method. In the electric furnace, converter after melting, initial blowing, and then placed in a vacuum tank (vacuum chamber) through the bottom of the argon stirring plus vacuum degassing process, in order to obtain pure liquid steel.

VD furnace is generally matched with the LF furnace, respectively, by the LF furnace to complete the composition, temperature adjustment, by the VD furnace to complete the degassing, stirring and other tasks. There are also in the VD furnace vacuum cover to install the oxygen gun smelting stainless steel, that is, become VOD furnace.

Role:

VD furnace is a widely used vacuum refining equipment, with good degassing and deoxidation effect, can effectively reduce the hydrogen and nitrogen content of steel, through the carbon and oxygen reaction to remove the oxygen in steel, through the alkaline top slag and the full reaction of the steel desulfurization, in addition to the function of uniform composition and temperature.