Steel production due to a variety of furnace working environment and service performance is not the same, so the refractory requirements are different.

Refractories for AOD furnaces

Since 1968, the American Joslin company invented the AOD steel refining method, since its application has been, has been rapidly popularized. So far, AOD steel refining method has become the main method of stainless steel refining. However, AOD furnace in the application process, its application conditions are very harsh, the erosion of the furnace lining is more serious. Therefore, in order to improve the life of the AOD furnace lining, the choice of excellent performance refractory material is very necessary. At present, countries around the world mainly use dolomite bricks, magnesium dolomite bricks and magnesium chromium bricks as refractory materials for AOD furnace lining. Among them, the production process of magnesium-chromium brick is complicated and has the disadvantages of high firing temperature, high energy consumption and high cost. In addition, magnesium-chromium refractories, at high temperatures, alkaline media and oxidizing atmosphere, Cr3+ in the material will be converted into Cr6+ with strong carcinogenicity, causing great harm to the human body and the environment, so magnesium-chromium bricks are gradually replaced by magnesium-calcium materials, magnesium-calcium refractories have become the first choice of the refractory materials for the lining of the current AOD furnace. Europe has abundant natural dolomite, its AOD furnace lining commonly used dolomite refractory materials, to be used in place of magnesium-chromium bricks, the package wall at the use of low-grade asphalt combined with the magnesium dolomite bricks or burnt magnesium dolomite turn, slag line at the use of high-temperature burnt magnesium dolomite bricks, the life of this AOD furnace lining than magnesium-chromium bricks lining low, but it can be used to make the cost of steelmaking is low, with the advantages of the economic benefits of the obvious.

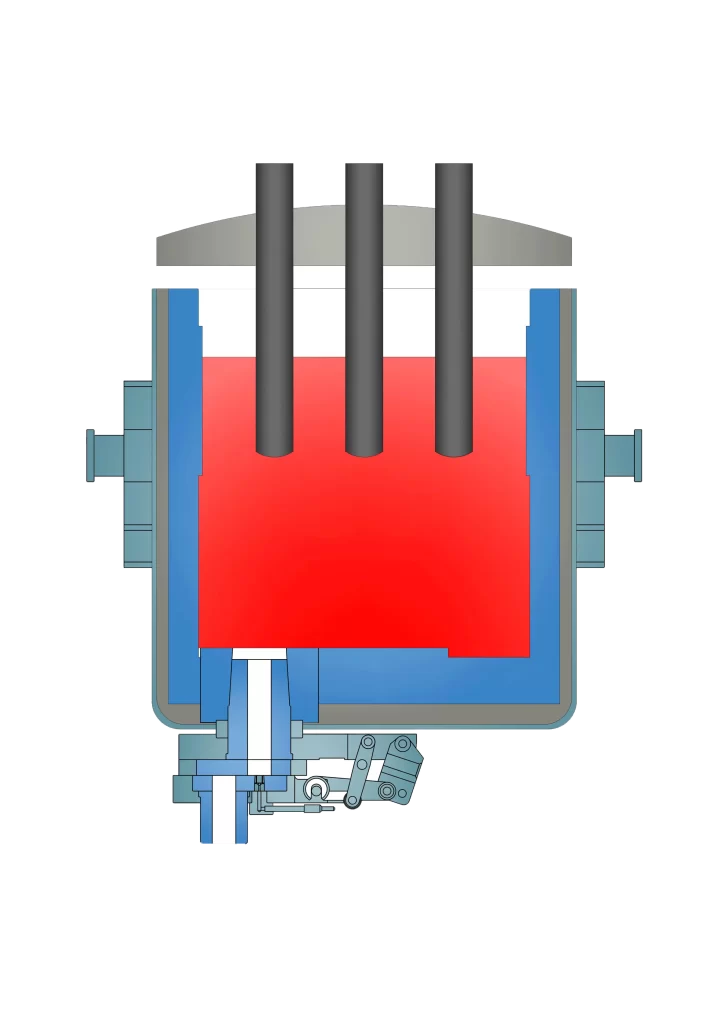

Refractories for Ladle furnace

LF furnace (ladle furnace) refining method developed by Japan Special Steel Company in 1971, is a kind of production technology through electric arc heating, argon gas stirring and refining slag as the core, the earliest is to refine the special steel mainly. The refractories for LF furnaces are selected on the basis of the type of steel to be refined, the refining temperature, the slag alkalinity, the stability and the cost, etc. The service life of the selected refractories for the lining of the furnaces is generally 50~100 times.

Refractories for RH furnaces

RH (steel vacuum cycle degassing) process is by the West Germany Ruhrsteel company (Ruhrstahl) and Heraeus (Heraeus) jointly developed, more than 50 years ago. RH process because of low investment in equipment, smelting efficiency, easy to operate and so on the advantages, so that it is widely used in steelmaking production. At the same time, RH process also has the characteristics of increasing steel production, improving steel quality, reducing cost, improving economic efficiency, etc. Its application in steel production makes the steelmaking process greatly optimized.The selection of refractory materials for RH furnace lining is decided according to the part where it is located and the temperature, atmosphere, chemical composition, vacuum degree and other factors. At present, the domestic RH furnace refractory materials used are mainly magnesium-chromium bricks, RH furnace upper slot lining refractory materials are generally not in direct contact with molten steel and slag, usually selected chrome direct combination of magnesium-chromium bricks; the middle of the slot working layer and molten steel and slag in direct contact with molten steel and will be subject to steel scrubbing, erosion of slag and the sudden change in temperature and other factors, generally selected chrome and then combined with magnesium-chromium bricks, insulation selected lightweight high alumina bricks; the lower slot will be subject to the temperature and atmosphere, vacuum, and other factors. The lower groove will be subject to continuous erosion of the slag, generally selected high-temperature firing of magnesium-chromium bricks.