Steel ladle refractory materials for liquid steel quality and temperature drop of the impact is multifaceted, based on this reality, in the use of steel ladle link, should be scientifically adjusted refractory material categories and ratios to ensure that its role is reasonable and effective to play for the subsequent production operations to create a good atmosphere.

(1) From the past situation, the material properties of ladle refractory will change from alkaline to neutral to acidic in the process of use, and the temperature is rising while the acidity and alkalinity are changing. Under the combined effect of the two factors, the oxygen potential index of the ladle refractory material is increasing, and the ability to transfer oxygen to the molten steel also shows a rising trend. The metal elements in the molten steel under the oxygen environment undergo oxidation reactions, resulting in a certain number of impurities within the molten steel, affecting the quality of the entire molten steel. Therefore, in order to ensure the quality of molten steel, the relevant enterprises in the ladle refractory material category selection, the need for refractory materials of oxygen potential index for strict assessment, from the source to avoid the use of ladle link, too much oxygen into the molten steel, to ensure the quality of molten steel.

(2) Steel ladle refractory particle ratio should be selected according to the use of steel ladle environment and processing requirements for a reasonable choice, once there is an imbalance in the ratio of particles, the quiet will be directly on the temperature control of the liquid steel to bring about an impact. In order to ensure the actual use of the effect, at present, most of the enterprises in China in the use of ladle link, the coarse, medium and fine three kinds of particles for reasonable deployment, in order to ensure the efficient use of refractory materials. From the structural composition of refractory materials, coarse particles are mainly used as the framework of refractory materials to ensure their own structural strength and prolong the service life of refractory materials, fine particles are the matrix of refractory materials, and ladle refractory strength and density have a close relationship. From the research data published by a scientific research organization, different particles in different ratios, the liquid steel temperature drop has a significant difference.

Through comparison, it is found that the particle ratio and particle size have the most direct influence on the temperature drop, taking into account the use of ladle refractory material environment and the demand for various parameters, combined with the quality of liquid steel and temperature drop control, should be carried out for the reasonable selection of ladle refractory material particle ratio, in the process, in order to ensure that the practicality of the particle ratio, the technicians need to comprehensively take into account the capacity of the ladle as well as the temperature of the particle Ratio for secondary optimization.

(3) In the production process, in order to ensure the quality of liquid steel, improve the temperature control ability of ladle, usually, need to bake the ladle to ensure that the ladle in the liquid steel transportation, processing process, the internal temperature curve out of a reasonable range. However, from the actual situation, most of the iron and steel enterprises and foundry enterprises in the production process, there is no baking treatment of the ladle, even if some of the staff of the enterprise to take the baking treatment, but due to the baking experience or the influence of other factors, the ladle heating curve is not set up reasonably, the role of the role of the difficult to play effectively. Steel ladle in the process of transportation, refining steel, water in the process of reaching its boiling point, in the form of gaseous form in the ladle refractory material to find gaps overflow. This rapid overflow of water vapor will leave a large number of holes inside the ladle refractory material, these holes make the liquid steel heat dissipation faster, the temperature drop difficulty is further increased.

Refractory materials in the water mainly from the sand adsorption of water, water crystals and all kinds of additives in the heat produced by the water, in order to ensure normal production activities, refractory materials in the water must be completely excluded below 800 ℃, if the temperature range of 800 ℃ or more, the refractory material is still residual moisture will lead to a large number of refractory material base body cellular cavity, which will lead to cracks, greatly affecting the safety of the subsequent production activities. This will lead to the emergence of cracks, which will greatly affect the safety of subsequent production activities. Therefore, in the process of using the ladle refractory material, in order to ensure temperature control performance, to ensure safe production, the ladle refractory material should be necessary drainage treatment, to avoid the water out of the impurity to the refractory material’s own structural strength and integrity of the damage. Out of this demand, technicians can use low-temperature baking method, the speed of water vapor overflow control within a reasonable range, to avoid overflow too fast, effectively prevent the emergence of refractory cracks.

(4) In the low-temperature baking process, in order to protect the baking effect of the ladle, the staff should be based on the characteristics of the baking curve of the refractory material, set the baking temperature and baking cycle reasonably, and rationalize the whole baking process. In actual operation, attention should be paid to the key nodes of 85℃, 200℃ and 800℃. Heating the refractory material temperature from room temperature to 85 ℃, the purpose is to effectively reduce the size of the pore size of the capillary channels in the ladle refractory material through low-temperature heating, reduce the rate of water vapor overflow, and ensure the structural integrity of the refractory material. The purpose of increasing the temperature from 85℃ to 200℃ is to rapidly complete the hardening and drying of the ladle heat-resistant material on the basis of the basic completion of the water vapor overflow, so as to improve the structural strength. The purpose of gradually increasing the temperature of the refractory material to 200℃ is to ensure the environmental adaptability of the heat-resistant material, so that it can effectively carry out various tasks under a variety of temperature environments, and create conditions for subsequent high-temperature operations.

More details about ladle refractory

What is ladle refractory?

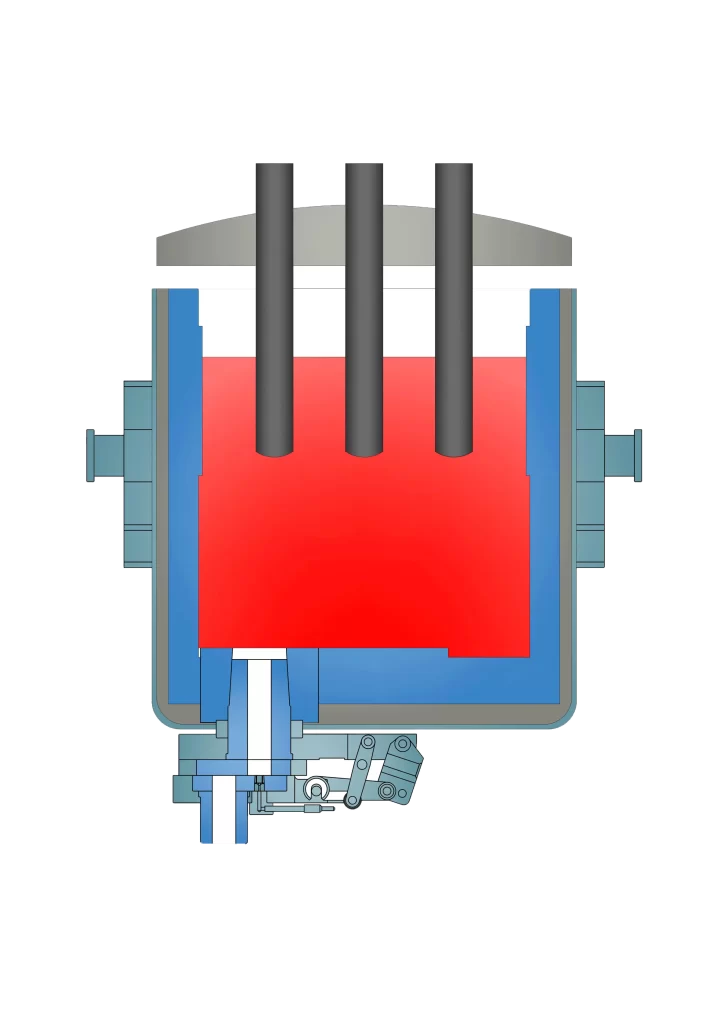

In the realm of refractories, the ladle is a term used for a vessel that is capable of withstanding extremely high temperatures of molten metals. This vessel is the primary medium to carry and transport these molten materials.

What is the ladle furnace treatment?

In the realm of refractories, the ladle is a term used for a vessel that is capable of withstanding extremely high temperatures of molten metals. This vessel is the primary medium to carry and transport these molten materials.

Why argon is used in ladle furnace?

Argon injection in ladle shrouds is customarily practised during teeming of molten steel from ladle to tundish to minimize air ingression and thereby, restrict atmospheric oxidation of steel melt.

What are the reactions in ladle furnace?

The ladle refining process involves deoxidation, alloying with ferroalloys, desulphurisation, removal or modification of inclusions, vacuum degassing, and adjustment of temperature for continuous casting.