Steel mill ladle is the role of the converter smelting steel transportation to the continuous casting, in the continuous casting ladle rotary table above, 1500 ℃ high temperature steel through the bottom of the ladle nozzle, slide out to the tundish, billet transit suspension, and ultimately from the tundish nozzle to the continuous casting of the pulling straightening, complete the billet molding. For high temperature steel from the ladle out of the nozzle, need to be placed in the nozlle well block internal, nozzle in the ladle use process, use 20-25 times can be replaced online, ladle well block must be in the small repair ladle, replacement of the bottom of the ladle to replace the ladle well block. The quality of ladle well block, construction quality directly affects the normal operation of ladle. The quality problems of ladle nozzle well block in the operation process usually have unstable material, knotting process control problems, baking is not in place, site construction and installation defects. The problems occurred in the field of ladle well block combing and solution, and finally achieved satisfactory results, to ensure the normal operation of ladle.

1. Ladle on-site utilization

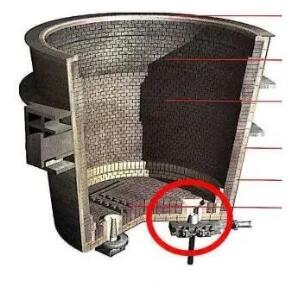

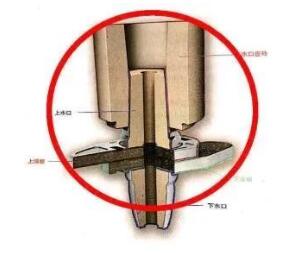

Steel plant using 150 tons of ladle, the use of double ladle nozzles, nozzles directly set in the ladle well block, well block in the masonry package bottom magnesium carbon brick installed in the bottom of the package, life and the bottom of the package synchronization, the service life of the package in the 70-80 furnace times between the whole ladle service life of 130-150 furnaces, the ladle the overall resistance schematic diagram is shown in Figure 1 below; ladle nozzle in the ladle baking is completed on-line before installation, the use of sealing glue. The sealant is applied on the outside of nozzle, and ladle nozzle is set into the well block by manual pressure, which makes the ladle well block. The sealant and the nozzle closely connected as a whole and increases the overall strength. The specific installation schematic is shown in Figure 2 below.

Figure 2:Lalde nozzle and well block

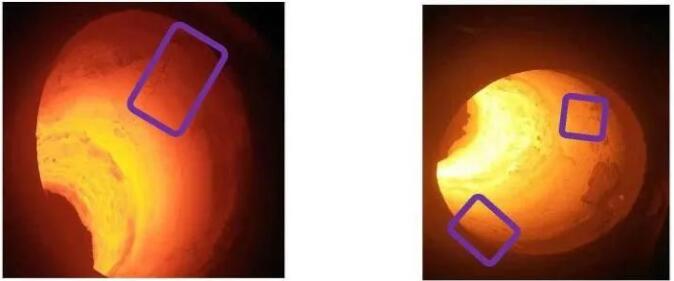

Ladle well block in the use of the process, the uppermost direct contact with the initial impact of the liquid steel, steel outflow process of continuous scouring, erosion, ladle well block length in the continuous shortening, ladle well block within the nozzle is the direct outflow channel of the liquid steel, bear the high temperature steel impact, friction and temperature difference in the production process of the change, the ladle well block connection rely on the sealing between the sealing mud for sealing. In 2019, one after another the phenomenon of cracked ladle nozzle block, found in a timely manner for offline processing, found untimely through the nozzle and the seat of the mud channel between lalde nozzle block nuisance steel through the package, seriously restricting the production rhythm of the scene, increasing the cost of the ladle, the production of a passive situation. Figure 3 for the online observation of the ladle well block cracks.

For the ladle well block cracks caused by the ladle well block channel and the nozzle between the leakage of steel accident, from the nozzle quality, composition, ladle well block quality, construction and other aspects of the analysis and tracking one by one, the ladle nozzle complete and undamaged, can be excluded; For the ladle well block cracks found, analyze the main ladle well block cracks, the integrity is not intact, the strength of the decline, while the seat of the gap between the brick and the ladle nozzle to increase the steel liquid seepage into the gap between the mud, the ladle well block, mud and ladle nozzle three linked as a whole strength was damaged, gradually eroded, thus appearing to breed steel, steel leakage accident. At the same time, the gap between the ladle well block and the ladle nozzle increases, the steel liquid seeps into the gap of the cement, the ladle well block, the cement and the ladle nozzle are connected to the overall strength of the city as a whole has been damaged, the sealing cement can not resist the high temperature of the hot steel liquid, gradually eroded, thus appearing to nuisance steel, leakage of steel accident.

2.Programmatic measures for steel leakage

For the ladle well block cracks appear cracks lead to leakage of steel accident, steelmaking and technology center personnel combined with manufacturers to analyze the reasons, on the one hand, from the ladle well block material by the manufacturers to analyze and deploy, at the same time, from other domestic ladle well block manufacturers emergency transfer quality and reputation of the company’s products for trial, the situation is as follows:

1) using A manufacturer ladle well block, use to the late stage (60 times ), found that there are micro-cracks, ladle well block upper part of the phenomenon of obvious expansion;

2) B manufacturer’s ladle well block off the line, found that there are also a number of longitudinal micro-cracks, cracks show 90 degrees between the distribution of the middle part of ladle well block (from the ladle hot repair platform at the personnel facing the ladle well block as a horizontal reference, the cracks are not in the four corners of the ladle well block).

3) The ladle contracting manufacturer analyzed the material of ladle well block, selected high-quality raw materials step by step formula operation, and at the same time adjusted the formula and composition of the internal aggregates and powders, the cracks occurring in the chances of gradual reduction;.

The following measures were taken for ladle well block installation operation:

Ladle well block in the installation with the bottom of the package together with the masonry, before the ladle well block installation and positioning, for ladle well block bottom of the steel structure at the location of the clean impurities, filled with good, the periphery of the use of casting material for vibration, filling, the overall construction is completed after the baking, on the line, the specific schematic diagram is shown in the following figure:

1) For the water-cement ratio of the castable material around ladle well block of the package is strictly controlled, and the moisture is controlled between 6-8%.

2) Construction of pouring material: for the gap between ladle well block and the bottom of the bag (30-100mm), the vibration process is operated manually, and the vibrating rod can not be used to vibrate, so as to avoid excessive vibration force and sinking of aggregates.

3) Check the ladle well block and erosion when replacing ladle nozzle.

4) Contact the dispatching, ladle off the line waiting for steel time more than 30min, should be the second baking.

5) Strict temperature monitoring during baking of ladle, designate special record book, mainly record the temperature of each part (bottom, wall, slag line, mouth), pay close attention to the exhaust condition of ladle nozzles and wall during baking.

6) Manufacturers combined with the technology center personnel, issued on-site ladle construction complete program on the wall, regular training.

3.Effect of remodeling

By repairing several aspects of ladle well block for nearly two months, the cracks of ladle well block are gradually reduced and disappeared, and the service life is within the controllable range, the direction and effect of the transformation are better, which curbed the production accidents and saved cost.

Steelmaking ladle is an important tool for steelmaking liquid steel transit, the internal quality of the refractory material quality and construction quality is directly related to the production of smooth and safe, for the daily management of the ladle and the deployment of the use of the steel plant technicians according to their respective working conditions to find out and summarize, for the above experience can be worthwhile to draw on and promote.