Making high alumina brick as following:

The most common way to manufacture high alumina brick is through the firing of bauxite, which naturally contains a blend of both aluminum oxide and something called “kaolinitic clay”, which is a clay composed of layered silica.

Once this material is fired it creates a composition of alumina and mullite, which is used as-is to create bricks.High alumina brick typically contains between 50-88% alumina, which is more than enough to lend the robust benefits of alumina to the refractory brick.

The manufacturing of high alumina brick is very similar; powdered bauxite is sintered with ceramic and fired at temperatures upwards of 1,470C, producing an enhanced fire brick with properties that defer greatly from both conventional ceramic and clay.

Manufacture of high alumina bricks

Method in the manufacture of high alumina refractory bricks containing more than 50% by weight alumina, in which moist refractory starting material is pressed into brick shapes, dried and hydrothermally bound. The principal binding agent used is finely divided activated alumina and is either added alone or together with any one of the substances slaked lime, slaked magnesia and finely divided silicon dioxide. The conditions chosen for the hydrothermal treament being such as to convert essentially all the activated alumina into boehmite.

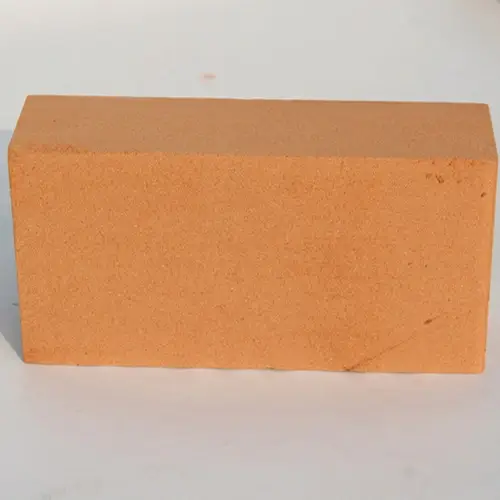

Refractory bricks (bricks that do not decompose due to high heat or pressure) are an integral component of any large-scale kiln or furnace operation. These bricks are important because they are used to line the interior of furnaces and kilns due to their low thermal conductivity.

FAQ:

What is High Alumina Brick?

High-alumina refractories are made from bauxite, a naturally occurring material containing aluminum hydroxide (Al[OH]3) and kaolinitic clays. These raw materials are roasted to produce a mixture of synthetic alumina and mullite (an aluminosilicate mineral with the chemical formula 3Al2O3 · 2SiO2).

Where are high alumina bricks used?

Depending upon the intrinsic features, Alumina Bricks are used for the lining of varieties of equipment like Blast Furnace; Hot Blast Stoves; Cement Kilns; Glass Tank Furnace; Pot Furnace; Anode Baking Furnace; Petro-chemicals; Fertilizers; Boilers; Coke Ovens; Hot Metal Ladles etc.

What are the properties of high alumina brick?

High Alumina bricks have great features like high temperature performance, great corrosion and wear resistance, high bulk density, low iron content, etc. High Alumina bricks are extensively used in mining, metallurgy, cement, chemical and refinery and refractory industries.

Is high alumina bricks acidic or basic?

Aluminosilicate refractories, rich in silica, are belonging to acidic refractories, while those rich in alumina are essentially of neutral type.